Net Zero, Carbon Neutral, & Embodied Carbon

By Jason Gaekwad, Technical Director – Building Physics and Sustainability

Introduction

This is the third in a series of short articles which cover concepts around ‘Net Zero’ and what it means for buildings and construction projects. The present article further unpacks concepts relating to ‘Net Zero’ and Carbon Neutrality, with a focus on the concept of embodied carbon. Previous articles in this series built context around climate change, the effects of the building and construction industry, and ideas around ‘green building’ and ‘Net Zero’

Further articles will discuss more detailed strategies and pathways to achieving Net Zero and Carbon Neutral projects.

Achieving Carbon Neutrality – Embodied Carbon

The previous article touched on ‘Net Zero’ as typically referring to operational carbon emissions only, with the term ‘Carbon Neutral’ referring to zero operational and embodied emissions.

The pathway to minimising operational carbon is generally quite clear in industry, with a focus on drastically reducing energy use, maximising on-site renewable energy generation, changing fuel sources (e.g. switching to a renewable energy provider), and (if necessary), purchase of carbon offsets. The pathway to minimising embodied carbon is often less well understood.

The term ’embodied carbon’ encompasses all carbon emissions associated with the creation, existence, and end-of-life of a building, except day-to-day operational carbon emissions. This includes all the energy (and associated carbon emissions) associated with the planning, construction, maintenance, refurbishment, and end-of-life of a building. This way of thinking highlights the importance of the amount of materials and products used in a building, and the history (and future) of each particular material and product used on site. For example, does a particular material use a large amount of fossil fuels in its manufacture (such as Portland cement)? Was a particular product transported inefficiently, or over a long distance, using fossil fuel based transport methods? Can a particular material have a high recycled content (such as steel), or be recycled itself?

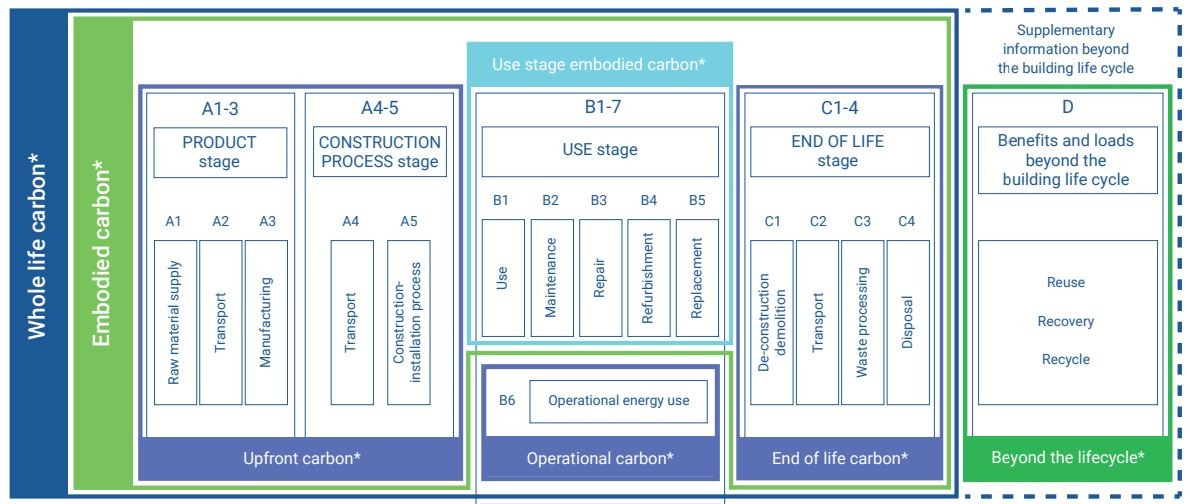

The Life Cycle Analysis concept of ‘system boundaries’ becomes quite important here. Often ‘cradle to gate’ data is discussed, which includes primary extraction (‘cradle’), manufacture and packaging, right to the ‘gate’ as the material or product exits the factory. However, this style of thinking doesn’t take transport, the construction process, or end-of-life into account. Cradle-to-grave, or cradle-to-cradle thinking is more appropriate here, which accounts for emissions associated with disposal or (hopefully) reuse/recycling. Figure 1 [1] displays the many stages and boundaries applicable in Life Cycle Analysis for embodied carbon. These techniques, which have been available for over 50 years, are critical is assessing and minimising embodied impacts. (The image top left is Figure 1 from WorldGBC and Ramboll (2019). Bringing Embodied Carbon Upfront – The various stages of the life cycle and definition of common terms, according to the commonly adopted standard EN 15978).

It is worth noting that, whilst operational carbon currently dominates the carbon emissions from the property and construction industries, embodied carbon is predicted to dominate in the future (refer Figure 2) [2]. This is due to the (hopeful) conversion of energy networks from fossil fuel dependent to renewable sources. However, this doesn’t mean that development of low operational carbon and energy buildings is no longer desirable. Low-energy buildings provide a multitude of benefits to building owners and occupants including low operational costs, climate and grid resilience, occupant comfort, lower absenteeism, increased productivity, etc. (The third image on the left is Figure 2 from GBCA and thinkstep-anz. (2021). Embodied Carbon and Embodied Energy in Australia’s Buildings and shows future estimates for carbon emissions from Australian building stock show embodied carbon dominating emissions.)

Challenges for Embodied Carbon

Embodied carbon emissions can be quite difficult to consider as availability of life cycle impact data from building products is often limited. However, the awareness of suppliers is slowly developing, with research bodies also assisting with creation of geographically specific datasets. These datasets attempt to capture the impact of any particular product across the whole life cycle and supply chain of the constituent raw materials.

It is worth noting that there is significant room for error in both the development of and application of various life cycle impact datasets. This is largely due to the broad scope, complexity, and non-specific nature of the data. There is advantage in using generic data sets for comparison and benchmarking, with application of geography and project specific materials, products, and designs developing throughout the design and construction phases of a project.

In the early stages of a project there can be challenges in determining benchmarks from which to reduce embodied carbon, and proposed materiality (material + volume or mass) of the design. Project specific definitions and targets are required at an early stage, often produced through research and investigation of case studies. Furthermore, optimisation of major assemblies or components of the design, such as optimising the typical structural system used in a building rather than assessing the structure of a whole building, can assist in providing design direction when levels of uncertainty are still high.

In Summary

This article further elaborated on the concepts of Carbon Neutrality and embodied carbon. Life cycle impacts were discussed, with a focus on construction materials and products. It is clear that development of the whole product and material supply chain is required to support Carbon Neutral developments. But materiality and life cycle impacts are only a small part of the overall Carbon Neutral story. We need to rethink every phase of projects, from owner wants and needs, to design approaches, product and material manufacture and supply, construction methodology, operation, and end-of-life methods. Much of these factors are external to the building design, occurring either upstream or downstream to the planning and design phases of a building project. The next article will take a step back and look at the overall pathway for Net Zero and Carbon Neutrality for a building project, from project ideation through to end-of-life.